In the elevator industry, there are greater demands for higher wear resistance of traction in sheaves. As traditional OEM sheaves fail to meet the optimised performance due to rapid wear and rifling in grooves.

The basic factor governing wear is the types of metal to metal wear and the most significant factors governing this are the following:

- Microstructure and hardness of the surfaces which are in contact.

- Loads on the surfaces.

- Speeds and frequency of the relative movements of these surfaces.

- Friction coefficients of the considered metals.

- Uneven loading of ropes on sheaves.

- Misalignment of ropes on sheaves.

All these factors accentuate the wear phenomena, and tend to lead towards replacement sheaves. By thermal coating a sheave with TRACTkote® the sheave life will be greatly extended. The coating has also proven to enhance the traction on the sheaves.

The TRACTkote® coating system for traction and diverter sheaves have been developed together with leading companies in the lift industry and has been used to prolong the life of sheaves. TRACTkote® coating is the ideal answer for the customised solution designed to protect against the wear created from cast iron sheaves and higher MPa ropes.

New functional surface coatings are creating improved wear characteristics for the sheaves. The importance of this TRACTkote® development becomes clear when you consider the typical application conditions and the increasing costs of continued maintenance along with any replacement costs.

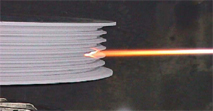

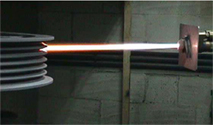

Coating a traction sheave with TRACTkote® using the HVOF (Diamond Jet Hybrid)